Textile Spindle Cleaning and Oiling Equipment

Spiraclean

– In last one decade or so, textile mills have switched over from Ring Frame spindle speed from 14000 to 23000. The old design spindle lubricating machine was not capable of fulfilling needs of spindle lubrication because most of these makers had no original technical knowhow by research but these machines were copied from one another. The technical knowhow of world trusted maker of JAPAN is implemented in a new generation machine SPIRACLEAN by EXEMPLAR ENTERPRISES. Almost all leading Textile Mill Groups of India use this machine for their high speed Ring Frames. A special design of nozzles accomplishes cleaning and lubricating of TFO also in a scientific way like in Ring Frame spindles. cleaning and lubricating device for spindle

Most Ring Frame users believe that Single Gun machine is suitable for them. In fact Single Gun is 50 years old technology. This old technology is now not in use since new technology machines came with two Guns. One independent Gun for cleaning and flushing and another Gun for Fresh oiling and topping. Following are the handicaps with single gun which are solved by two Gun Machines.

- Fresh oil and used oil comes in contact.

- Oil is wasted since during process there is likelihood of extraction of good oil with old oil.

- Topping feature is not available.

- Oil wastage is more as good oil is wasted when it is extracted along with used oil during flushing. Since topping is not possible mills are forced to completely change the oil during when topping cycle is due. The oil which is present in the bolster is not fully utilised and has a life still left. But this oil is unnecessarily wasted.

- Spiraclean with double Gun gives all justice to spindle to perform well, improvement in quality due to better performance of spindle, cost saving to management by optimum utilisation of oil life without wasting the same.

Textile Spindle Cleaning Equipment, Textile Spindle Cleaning Equipment, Textile Spindle Cleaning Equipment, Textile Spindle Cleaning Equipment, Textile Spindle Cleaning Equipment

Cleaning Gun

Oiling Gun (Topping Gun)

Textile Spindle Cleaning Machine

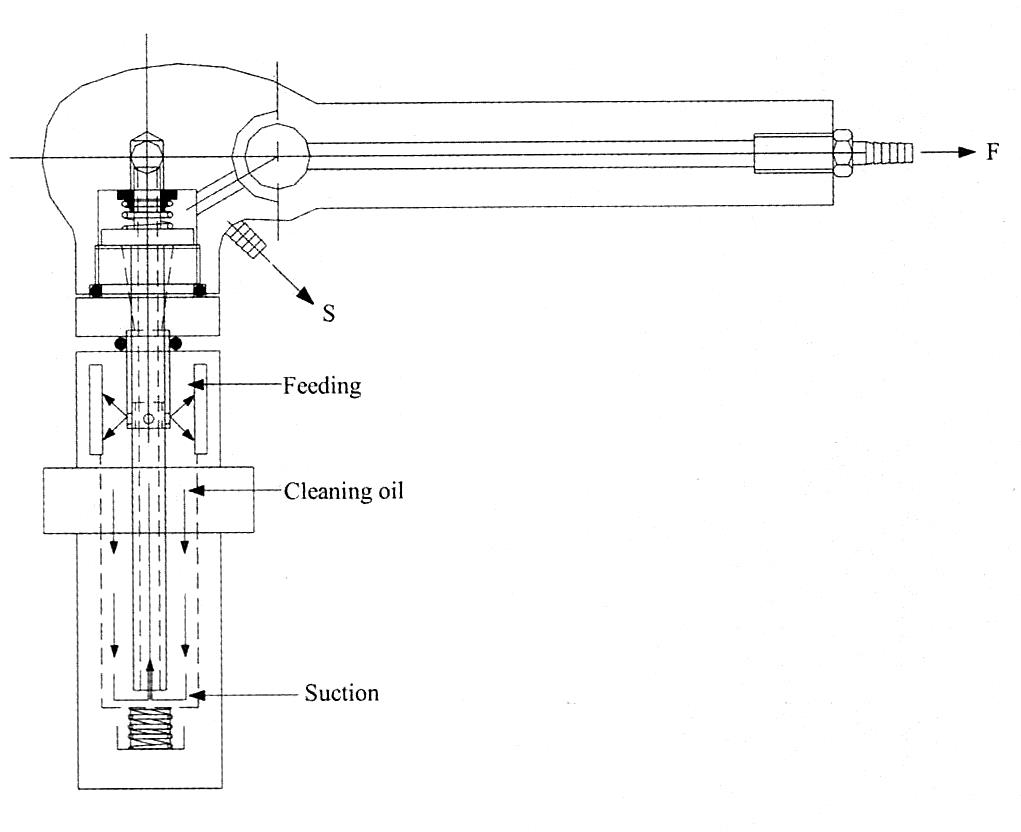

CLEANING :

- Due to simultaneous suction and feeding, used oil is extracted and filtered and redelivered in the insert achieving through flushing and cleaning.

- During flushing under pressure neck bearing also gets cleaned. Thus improves insert and Spindle life.

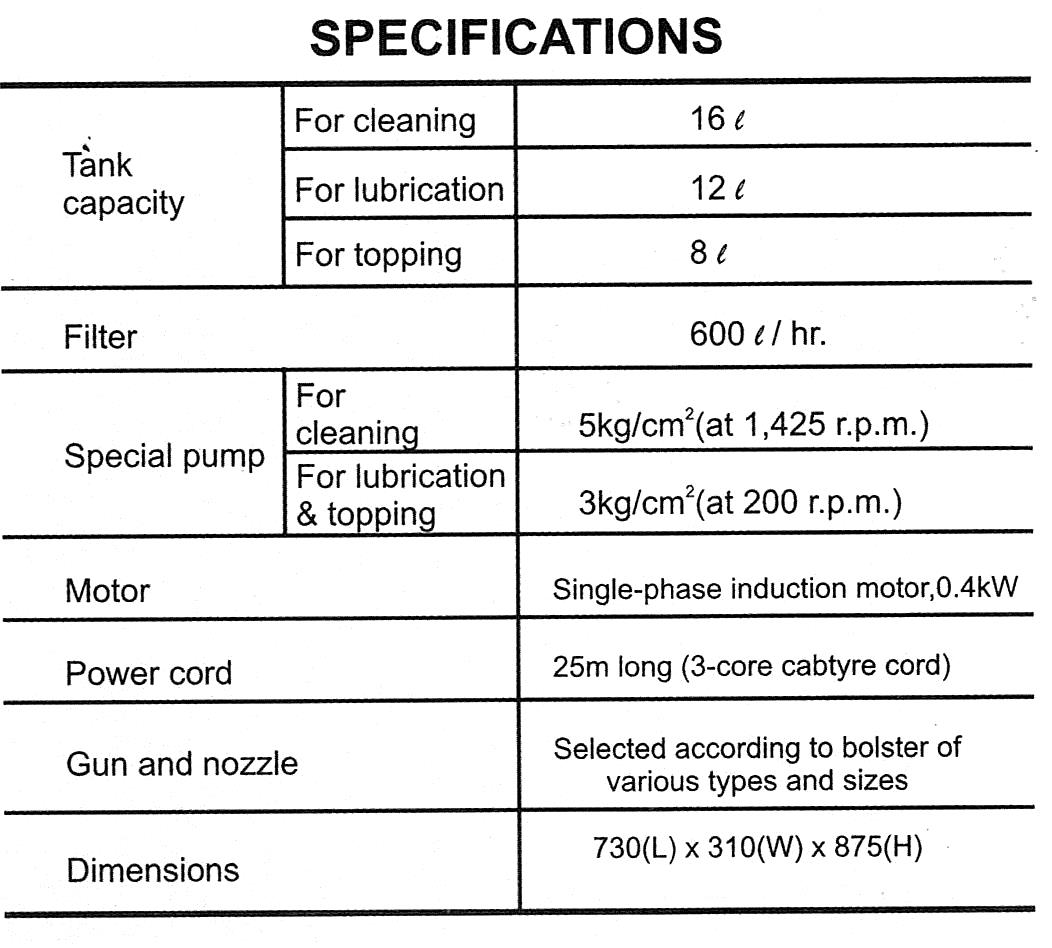

- Same machine can be used for various types and sizes of bolsters.

- No extra oil needed during cleaning since extracted oil is used through filter.

- Simple for operation and maintenance. Easily moved among machines.

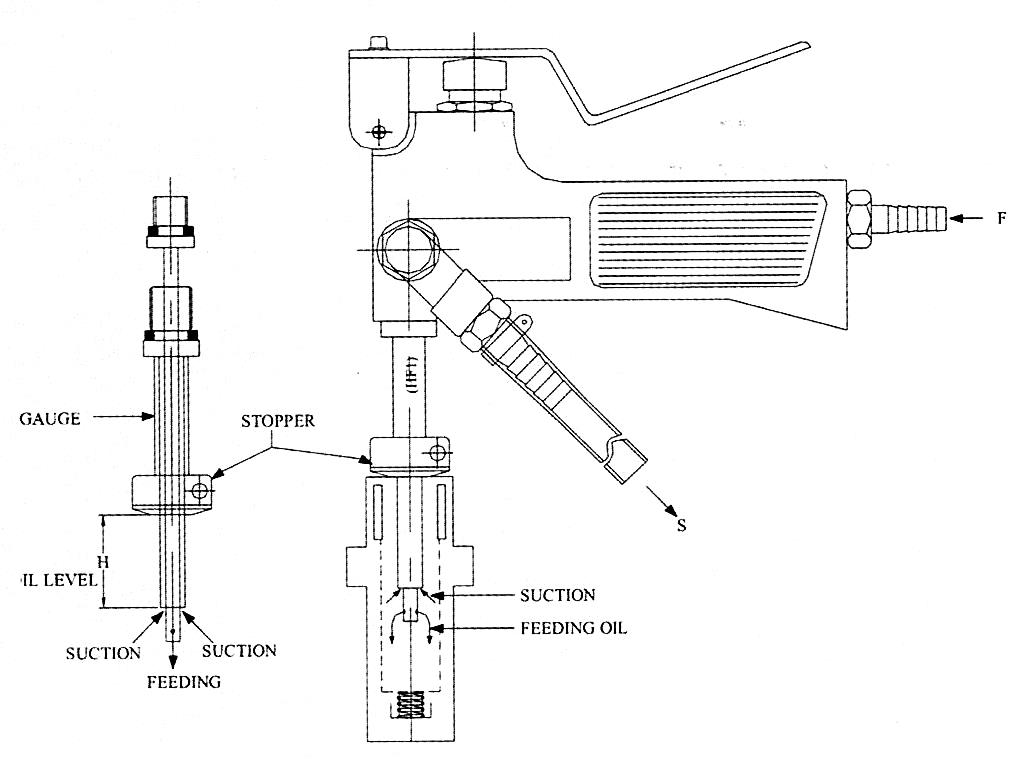

LUBRICATION :

- Nozzle design (H) predetermines exact quantity of oil delivered in insert.

- Fresh oil delivered during topping without stirring existing residual oil.

- No chance of manual error during deciding oil quantity to be delivered.

- No need of checking of oil level before topping.

- Only machine with 3 separate tanks for cleaning, oiling & topping.

* Cleaning oil tank wit cleaning operation only.

* Oiling tank with fresh oil for inserts.

* Topping tank ensures no used oil is mixed up with fresh oil.  Special design of guns allows lubrication without removal of ring rail to avoid time loss for removal and imbalance of ring rail.

Special design of guns allows lubrication without removal of ring rail to avoid time loss for removal and imbalance of ring rail.

Our other Links :